Preparing for disruptions with a risk register & scenario planning

6th April 2023

Noel Thomson, CEO of Synergic Technologies and supply chain expert, presented a webinar for New Zealand Trade and Enterprise customers about the best ways to build supply chain resilience by being prepared for disruptions, which focuses on the benefits of creating a risk register and scenario planning, while using technology, and managing supply relationships.

Learn how to protect your business's supply chain from disruption with a risk register and scenario planning. In this article you'll find a tool to help you create your own risk register and a checklist for scenario planning.

Creating a risk register and doing some scenario planning is the best way to prepare for disruptions to your supply chain. You want to do these as ongoing sessions with your team, monthly or quarterly, so you know what the smartest course of action is when faced with disruption. Have it written down as a plan that everyone in your business can follow.

Create a risk register

Building supply chain resilience starts with creating a register to understand risks that are critical to your business.

Download risk register tool

Use this tool to rank your supply chain risks from low to critical, in terms of impact on your business.

How to use this tool

Get in a room with your team and a whiteboard.

You’ll need a thorough understanding of your industry, market trends and potential disruptors to properly identify the risks to your supply chain.

What to discuss

What are some key problems or issues we’ve faced in the last 12-24 months and what’s the likelihood of these returning/getting worse over time?

What seasonality impacts might we fact (weather, technology, what’s happening in our industry/coming up?)

You can do a simple PESTELB analysis (political, economic, sociological, technological, legal, environmental, and biological) to get started.

Remember to use simple language and review your risk register once a month/quarter. Ask yourselves: Are these still relevant? Are there new risks? Jot these new risks down and create some scenario plans for those you’ve identified as critical, high or moderate.

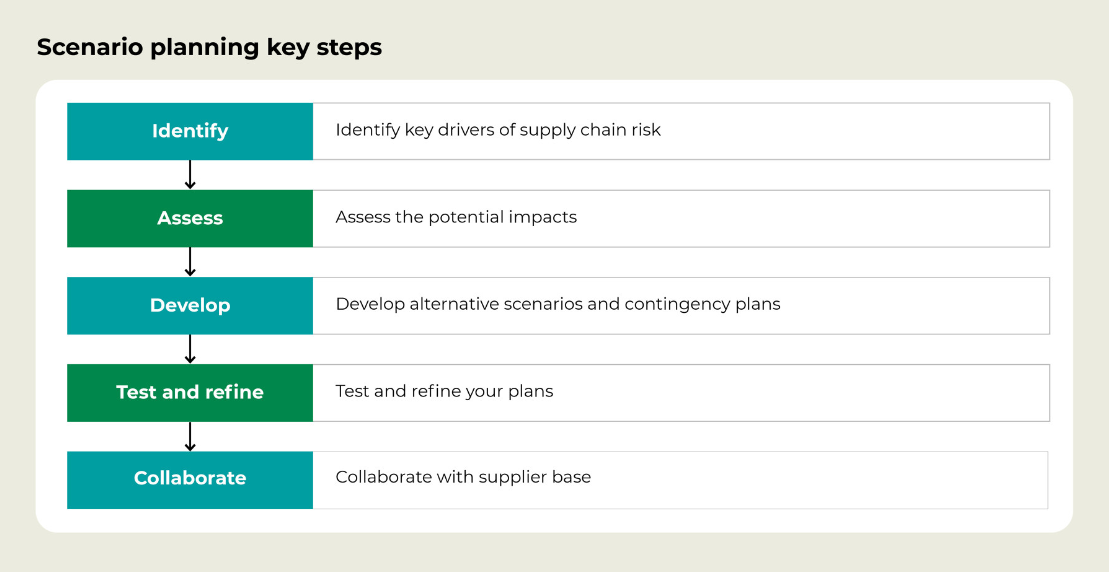

How to do scenario planning

After identifying some of your key supply chain risks, you now want to plan out some different scenarios if faced with the more critical ones.

When coming up with your scenario outcomes, think about the non-obvious ones. Doing a bit of detailed analysis might help realise you have more options available than you think.

Add real data to these scenarios

You want to add real data to these scenarios. You can get this data from your:

Sales forecasts

Capacity plans

Inventory policies

Lead times

Operating costs

Freight rates

Industry trends

Key performance indicators

To create scenario models you can use tools that are as simple and cheap as a whiteboard and Excel spreadsheets. Depending on the size and complexity of your business you might have ERP (enterprise resource planning) systems in place. If you do, you can use your supply chain plans to simulate these scenarios.

Supply chain tools that help with scenario planning

Scenario planning checklist

Download this checklist and use it to make sure you are well prepared for disruptions to your supply chain.

If you like to learn more about the latest news, emerging technology and events within the supply chain world, please visit the page below on NZTE’s website:

Learn how to grow your business overseas with myNZTE's free tools & guides - myNZTE

If you are interested in talking to a supply chain specialist about strengthening and creating a more resilient supply chain for your company, contact us by clicking the link below: